-

Alfred***We received the goods, everything went fine. Perfect packaging, good product quality, good price - we are satisfied.

Alfred***We received the goods, everything went fine. Perfect packaging, good product quality, good price - we are satisfied. -

May***The product quality is very good, beyond my expectations, the actual use of fully meet my needs, we will buy again.

May***The product quality is very good, beyond my expectations, the actual use of fully meet my needs, we will buy again. -

Matthew***I bought low expansion alloy from Joy, She is a very responsible lady, Huona's products quality is pretty good.

Matthew***I bought low expansion alloy from Joy, She is a very responsible lady, Huona's products quality is pretty good.

High Precision 4J29 Alloy Wire For Fe-Ni-Co Wire Kovar Type Sealing Alloy

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Thermal Expansion (30–300°C) | ~5.0 X 10⁻⁶ /°C | Density | ~8.2 G/cm³ |

|---|---|---|---|

| Resistivity | ~0.42 μΩ·m | Tensile Strength | ≥ 450 MPa |

| Elongation | ≥ 25% | Diameter | 0.02 Mm – 3.0 Mm |

| Highlight | High Precision glass sealing alloy wire,High Precision Low Expansion Alloy,SGS glass sealing alloy wire |

||

Product Overview:

4J29 alloy wire, also known as a Fe-Ni-Co sealing alloy or Kovar-type wire, is widely used in applications requiring glass-to-metal hermetic sealing. It contains approximately 29% nickel and 17% cobalt, which gives it a controlled thermal expansion closely matched with borosilicate glass. This makes it ideal for use in electronic tubes, vacuum relays, infrared sensors, and aerospace-grade components.

Material Composition:

-

Nickel (Ni): ~29%

-

Cobalt (Co): ~17%

-

Iron (Fe): Balance

-

Other elements: trace amounts of Mn, Si, C, etc.

Thermal Expansion (30–300°C): ~5.0 x 10⁻⁶ /°C

Density: ~8.2 g/cm³

Resistivity: ~0.42 μΩ·m

Tensile Strength: ≥ 450 MPa

Elongation: ≥ 25%

Available Sizes:

-

Diameter: 0.02 mm – 3.0 mm

-

Length: on spools, coils, or cut lengths as required

-

Surface: Bright, smooth, oxidation-free

-

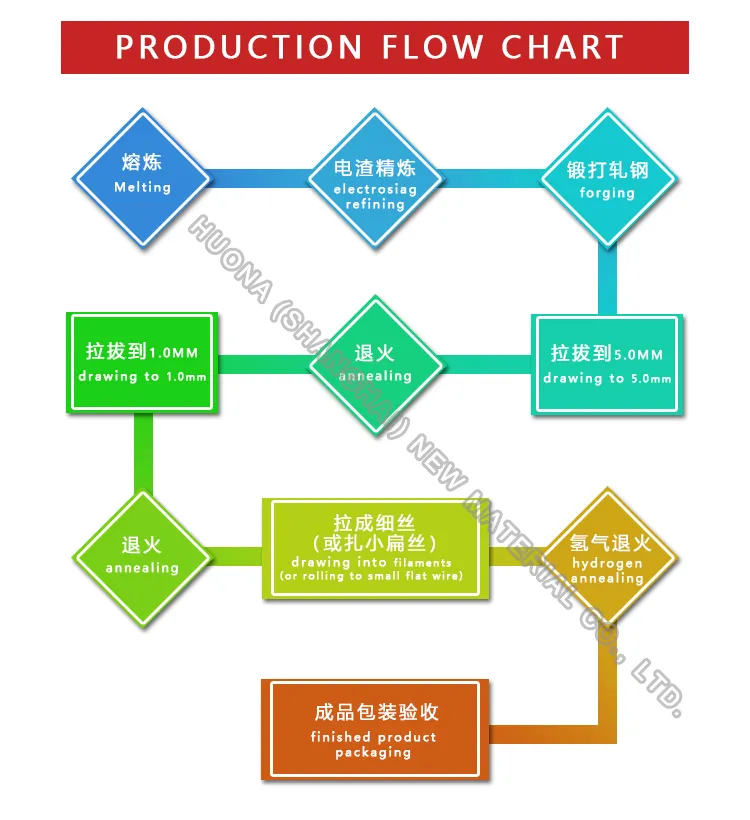

Condition: Annealed or cold drawn

Key Features:

-

Excellent thermal expansion compatibility with hard glass

-

Ideal for hermetic sealing in electronic and aerospace applications

-

Good weldability and high dimensional accuracy

-

Stable magnetic properties under various environmental conditions

-

Custom diameters and packaging options available

Typical Applications:

-

Vacuum relays and glass-sealed relays

-

Infrared and microwave device packaging

-

Glass-to-metal feedthroughs and connectors

-

Electronic tubes and sensor leads

-

Hermetically sealed electronic components in aerospace and defense

Packaging & Shipping:

-

Supplied in plastic spools, coils, or vacuum-sealed bags

-

Anti-rust and anti-moisture packaging optional

-

Shipping available by air, sea, or express

-

Delivery time: 7–15 working days depending on quantity

Handling and Storage:

Keep in a dry, clean environment. Avoid moisture or chemical exposure. Re-annealing may be needed before sealing to ensure optimal bonding with glass.