-

Alfred***We received the goods, everything went fine. Perfect packaging, good product quality, good price - we are satisfied.

Alfred***We received the goods, everything went fine. Perfect packaging, good product quality, good price - we are satisfied. -

May***The product quality is very good, beyond my expectations, the actual use of fully meet my needs, we will buy again.

May***The product quality is very good, beyond my expectations, the actual use of fully meet my needs, we will buy again. -

Matthew***I bought low expansion alloy from Joy, She is a very responsible lady, Huona's products quality is pretty good.

Matthew***I bought low expansion alloy from Joy, She is a very responsible lady, Huona's products quality is pretty good.

Inconel 625 Welding Wire (Ni-Cr-Mo Superalloy) ERNiCrMo-3 Filler Metal for High-Temperature & Corrosion-Resistant Welding

| Process Compatibility | MIG / TIG / SAW / Arc Spray / Flame Spray | Working Temperature | Up To 1000°C |

|---|---|---|---|

| Mechanical Strength | High (Suitable For Load & Thermal Cycling) | Corrosion Resistance | Excellent, Incl. Chlorides & Oxidizing Chemicals |

| Condition | Spool Wire / Rod Form | Spool Weight | 1kg / 5kg / 15kg / Custom |

| Supply Capacity | 40–60 Tons/month | Lead Time | 3–7 Days (standard Sizes) |

| Highlight | Inconel 625 welding wire,Ni-Cr-Mo superalloy filler metal,high-temperature corrosion-resistant welding wire |

||

Inconel 625 Welding Wire (Ni-Cr-Mo Superalloy)

ERNiCrMo-3 Filler Metal for High-Temperature & Corrosion-Resistant Welding

Available Diameters: 1.0 mm / 1.2 mm / 1.6 mm

Product Overview

Inconel 625 welding wire (ERNiCrMo-3) is a nickel-chromium-molybdenum-niobium superalloy filler metal.

It provides exceptional resistance to high-temperature oxidation, seawater corrosion, chloride pitting, crevice corrosion, and stress-corrosion cracking.

Commonly used for joining and overlaying Ni-based alloys, stainless steels, and dissimilar metals in chemical processing, marine, aerospace, energy and offshore equipment.

Chemical Composition (Typical)

| Element | Content (%) |

|---|---|

| Nickel (Ni) | Balance |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium + Tantalum (Nb+Ta) | 3.15 – 4.15 |

| Iron (Fe) | ≤ 5.0 |

| Others | Trace |

Conforms to: ASTM / AWS ERNiCrMo-3 (Inconel 625)

Key Features

-

Excellent corrosion resistance in seawater, acids, and chloride media

-

High temperature strength & oxidation stability up to ~980°C

-

Crack-resistant welds with strong metallurgical bonding

-

Suitable for dissimilar metal welding (Ni-base ↔ stainless steel)

-

Smooth feeding & stable arc characteristics

Application Areas

-

Chemical & Petrochemical: Heat exchangers, reactors, pipelines

-

Marine & Offshore: Pump shafts, seawater system components

-

Aerospace: Engine components, exhaust systems

-

Nuclear & Power Generation: Boiler tubing, overlay protection

-

Repair & Overlay Cladding: Wear + corrosion protective surfacing

Technical Specifications

| Item | Value |

|---|---|

| Alloy Grade | Inconel 625 |

| AWS Grade | ERNiCrMo-3 |

| Material Type | Ni-Cr-Mo-Nb Superalloy |

| Main Diameters (主推) | 1.0 mm / 1.2 mm / 1.6 mm |

| Other Diameters | 2.0 / 2.4 / 3.2 mm on request |

| Form | Spool Wire / Straight Rod |

| Welding Processes | TIG / MIG / SAW / Arc Spray / Flame Spray |

| Service Temperature | Up to ~980°C |

| Coating Appearance (Sprayed) | Dense silver-gray metallic finish |

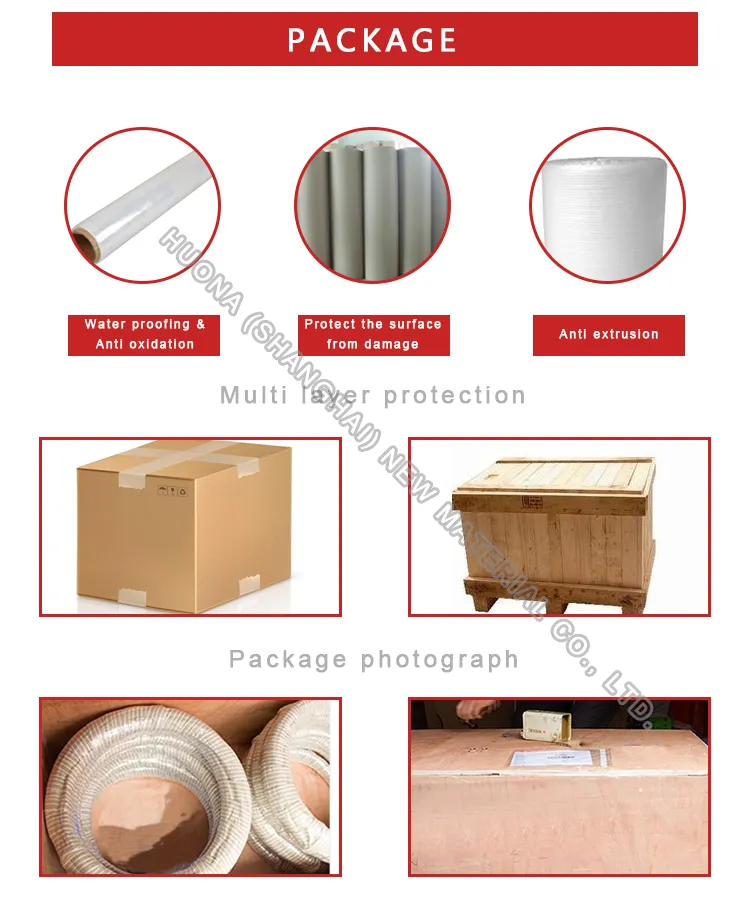

Packaging & Supply

-

Spools: 1kg / 5kg / 15kg / 20kg

-

Rods: 5kg per plastic tube

-

OEM & private label branding available

-

Export pallet packing available

Stock: Regular inventory available

Capacity: ~40–60 tons/month

Lead Time: 3–7 days (standard) | 10–15 days (custom)

Custom Attributes (可直接复制到环球广贸 / 阿里后台)

| Attribute Name | Attribute Value |

|---|---|

| Product Name | Inconel 625 Welding Wire |

| AWS Grade | ERNiCrMo-3 |

| Alloy Type | Ni-Cr-Mo-Nb Superalloy |

| Main Diameters | 1.0 mm / 1.2 mm / 1.6 mm |

| Wire Form | Spool / Rod |

| Welding Methods | TIG / MIG / SAW / Arc Spray / Flame Spray |

| Temperature Resistance | Up to ~980°C |

| Corrosion Resistance | Excellent in seawater & chloride media |

| Packaging | Spool / Tube / Carton / Pallet |

| Monthly Supply | 40–60 tons |

| Origin | China |

Tags:

Tags:

thermal arc spray wire

spray wire

flame spray nickel alloy wire