-

Alfred***We received the goods, everything went fine. Perfect packaging, good product quality, good price - we are satisfied.

Alfred***We received the goods, everything went fine. Perfect packaging, good product quality, good price - we are satisfied. -

May***The product quality is very good, beyond my expectations, the actual use of fully meet my needs, we will buy again.

May***The product quality is very good, beyond my expectations, the actual use of fully meet my needs, we will buy again. -

Matthew***I bought low expansion alloy from Joy, She is a very responsible lady, Huona's products quality is pretty good.

Matthew***I bought low expansion alloy from Joy, She is a very responsible lady, Huona's products quality is pretty good.

NiAl 95-5 Thermal Spray Wires Nickel Aluminum Self Bonding Alloy For Metal Surface Coating

| Place of Origin | CHINA |

|---|---|

| Brand Name | HUONA |

| Certification | ISO9001 |

| Model Number | WIRE |

| Minimum Order Quantity | 1KG |

| Price | Bargain |

| Packaging Details | Plastic film inside , wooden box outside , choose the suitable packing, Alos it can be customized by the clients' demand. |

| Delivery Time | A WEEK |

| Payment Terms | T/T |

| Supply Ability | 50 Ton/Tons per Month NiAl 95-5 |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Place Of Origin | Shanghai, China | Application | Thermal Spray Coating |

|---|---|---|---|

| Model Number | NiAl 95-5 | Material | Prime Raw Material |

| Standard Sizes | 1.60 And 2.00 Mm ( 0.0693 And 0.0787 Inch). | Other Sizes | Can Be Offered On Request. |

| Highlight | Self Bonding Thermal Spray Wire,Self Bonding high nickel welding wire,Corrosion Protection Thermal Spray Wire |

||

Good Quality NiAl 95-5 Thermal Spray Wires Nickel Aluminum 95/5 Thermal Spray Wire | Self-Bonding Alloy for Metal Surface Coating

Good quality NiAl 95-5 Thermal Spray wires

NiAl 95/5: Thermal Spray Wire (Sp 95/5, SD 95/5, Ni95Al5)

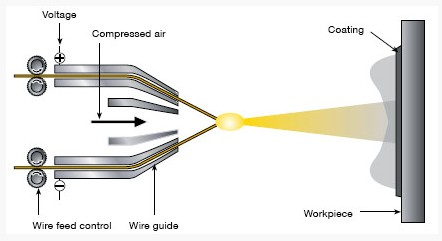

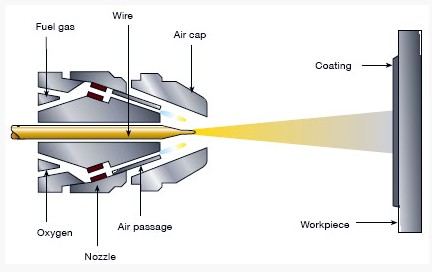

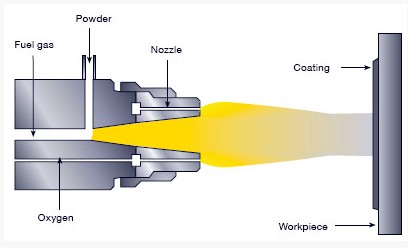

NiAl 95/5 is an austenitic nickel-aluminium alloy (NiAl alloy) for use in arc and flame spray systems. The alloy produces dense, well bonding coatings.

Typical applications for NiAl95/5 are bond coats, as protective coatings against high-temperature oxidation, protective coatings against scaling of conventional iron base alloys and as build-up coatings for dimensional restoration.

Application or Properties: Spray wire with excellent bonding strength. Sprayed layers of this material are-resistant to variation in high temperatures and are used as a buffer layer for all other spraying alloys. Hardness, coating macro: approximately HRc 22. Maximum working temperature: approximately 800° C. Layer thickness: approximately 0.1-0.15 mm.

Chemical composition

| Al % | Ni % | |

| Nominal composition | Bal. | |

| Min | 4.5 | |

| Max |

Packaging:Products are generally supplied in standard cardboard boxes, pallets, wooden boxes. Special packaging requirements can also be accommodated. (also depend on the customers' requirements)

For the Thermal spray wires , we pack the wires on spools. Then put spools into cartons, Then put the cartons onto pallet.

Shipping: We cooperation with many logistics company,We can provide express, sea transportation, air transportation, and rail way transportation based on customers' requirement.

1) We can provide a free sample for testing.

2) Customized lable, packing, OEM service

3) Mill test certificate will be provided after production, If it is necessary.

4) Good packing methods to keep goods no damage during delivery

5) We are cooperation with many famous forwarder, will try our best to choose the safty, convenience, quick, and cheap mode of transportation for our customers.

Capacity and Main markets. Our company has more than 20 years of experience in alloy products. The company covers 10000m2.The annual output reaches 5000 tons. The products apply to chemical industry, metallurgy mechanism, glass industry, ceramic industry, home appliance area widely. In china, we mainly do business with army industry, and for worldwide, our selling net-work has expanded to Russia, Ukraine, Germany, Iran, India, Itlay, America etc.

Quality Assurance. According to international standard, we introduce new techniques and new processes, so we can keep improving product quality. There are strict processes and quality manages to make sure the products keep updated, and be well received by users.

Equipment. Our major equipment, vacuum induction furnace, intermediate frequency induction furnace, electroslag furnace, skanthal A1 bath furnace, wiredrawing units, heat treatment production line and soon. Test equipment: straight reflection spectrograph , spectrometer , chemical analyse lab , machinery properties lab (omnipotent test machine,hardness test machine inside), also metallography laboratory, ultrasonic harmless test,etc.