-

Alfred***We received the goods, everything went fine. Perfect packaging, good product quality, good price - we are satisfied.

Alfred***We received the goods, everything went fine. Perfect packaging, good product quality, good price - we are satisfied. -

May***The product quality is very good, beyond my expectations, the actual use of fully meet my needs, we will buy again.

May***The product quality is very good, beyond my expectations, the actual use of fully meet my needs, we will buy again. -

Matthew***I bought low expansion alloy from Joy, She is a very responsible lady, Huona's products quality is pretty good.

Matthew***I bought low expansion alloy from Joy, She is a very responsible lady, Huona's products quality is pretty good.

Sulzer Metco Metcoloy 2/TAFA 60T/60E 13% Chrome Steel Thermal Spray Wire

| Place of Origin | CHINA |

|---|---|

| Brand Name | HUONA |

| Certification | ISO9001 |

| Model Number | WIRE |

| Minimum Order Quantity | 1KG |

| Price | Bargain |

| Packaging Details | Plastic film inside , wooden box outside , choose the suitable packing, Alos it can be customized by the clients' demand.(TAFA 60T/60E 13% Chrome Steel ) |

| Delivery Time | A WEEK |

| Payment Terms | T/T |

| Supply Ability | 30 Ton/Tons per Month TAFA 60T/60E 13% Chrome Steel |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Thermal Spray Coating | Place Of Origin | Shanghai, China |

|---|---|---|---|

| Model Number | 60E 13% Chrome Steel | Material | Prime Raw Material |

| Chemical Composition | TAFA 60T/60E 13% Chrome Steel Thermal Spray Wire | Weight Of Per Coil | 15kg |

| Standard Sizes | 1.60 And 2.00 Mm ( 0.0693 And 0.0787 Inch). | ||

| Highlight | Arc Bonding Layer TIG Welding Wire,Arc Bonding Layer Nickel Alloy Wire,1.60mm TIG Welding Wire |

||

Product descriptions from the supplier

Sulzer Metco Metcoloy 2/TAFA 60T/60E 13% Chrome Steel thermal spray wire

Product Description – Metcoloy 2 / TAFA 60T / TAFA 60E Thermal Spray Wire

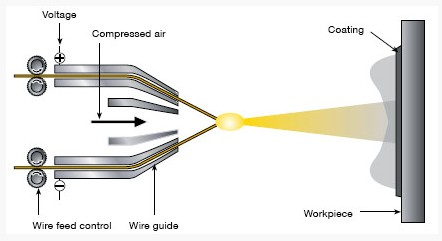

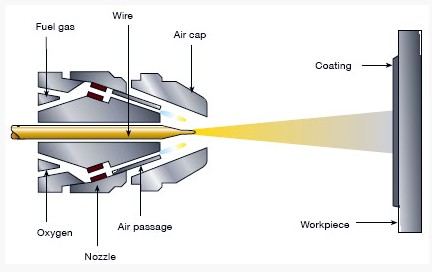

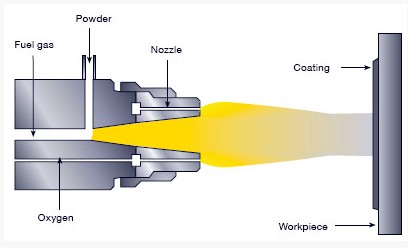

Metcoloy 2, TAFA 60T, and TAFA 60E (13% Chrome Steel) are high-performance thermal spray wires designed for arc spray and flame spray systems. Each wire offers distinct advantages tailored for surface restoration, wear protection, and corrosion resistance across a wide range of industrial applications.

Thermal Spray Wire Technical Comparison Table

| Product Name | Metco Metcoloy 2 | TAFA 60T | TAFA 60E (13% Chrome Steel) |

|---|---|---|---|

| Base Composition | Nickel-based alloy | Iron-based alloy | Low-carbon steel with ~13% Chromium |

| Typical Chemistry | Ni ≥ 95%, trace B, Si | Fe > 95%, minor C, Si, Mn | Fe balance, Cr ~13%, C ~0.1–0.2%, Mn, Si |

| Coating Hardness | ~ HRB 90–100 (machinable) | ~ HRC 20–30 | ~ HRC 35–45 |

| Bond Coat Needed | No (self-bonding) | Yes (recommended for critical surfaces) | Yes (typically used with bond coat) |

| Coating Density | High (dense and smooth finish) | Medium | Medium–High |

| Machinability | Excellent | Good | Moderate (grindable) |

| Wear Resistance | Moderate | High | High |

| Corrosion Resistance | Good (oxidation resistant) | Moderate | Moderate–Good (due to Cr content) |

| Applications | Aerospace parts, pump shafts, rollers | Hydraulic rods, general industrial repair | Shafts, sleeves, sealing surfaces, rebuild |

| Spray Method | Flame Spray / Arc Spray | Arc Spray | Arc Spray |

| Recommended Wire Sizes | 1/8", 3/32", 2.0 mm | 1/8", 2.0 mm | 1/8", 2.0 mm |

| Recommended Spray Parameters | Flame spray: Oxy-Acetylene: 35–45 psi Arc spray: 200–300 A / 28–32 V |

Arc Spray: 250–350 A / 30–35 V | Arc Spray: 250–350 A / 30–36 V |

| Packaging | Spools / Coils | Spools / Coils | Spools / Coils |

| Compatibility | Universal – Metco / TAFA / Oerlikon systems | TAFA Arc Spray Equipment | TAFA / Oerlikon / Generic Arc Spray Systems |