All Products

-

Alfred***We received the goods, everything went fine. Perfect packaging, good product quality, good price - we are satisfied.

Alfred***We received the goods, everything went fine. Perfect packaging, good product quality, good price - we are satisfied. -

May***The product quality is very good, beyond my expectations, the actual use of fully meet my needs, we will buy again.

May***The product quality is very good, beyond my expectations, the actual use of fully meet my needs, we will buy again. -

Matthew***I bought low expansion alloy from Joy, She is a very responsible lady, Tankii's products quality is pretty good.

Matthew***I bought low expansion alloy from Joy, She is a very responsible lady, Tankii's products quality is pretty good.

Low Expansion Alloy Wire 4j50 Nickel Iron Alloy 52/Feni52 Coils Wire

Contact me for free samples and coupons.

WhatsAPP:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Model NO. | Alloy 52 | Transport Package | DIN Spool, Carton, Wooden Case |

|---|---|---|---|

| HS Code | 7505220000 | Specification | Customized |

| Origin | Jiangsu, China | Production Capacity | 1500tons/Year |

| Highlight | Heat Resistant Low Expansion Alloy,Heat Resistant Nickel Iron Alloy,Feni52 Low Expansion Alloy |

||

Product Description

Product Description

Low Expansion Alloy Wire 4j50 Nickel Iron Alloy 52 / Feni52 Coils Wire

4J50, also known as a Nickel-Iron Controlled Expansion Alloy, is a precision alloy composed of approximately 50% Nickel and 50% Iron. It is specifically designed to provide thermal expansion characteristics compatible with hard glass, ceramics, and other sealing materials. This makes 4J50 ideal for glass-to-metal seals, electronic vacuum devices, and air-tight packaging.

| Property | Value |

|---|---|

| Alloy Name | 4J50 (Nickel-Iron Controlled Expansion Alloy) |

| Chemical Composition | Ni: ~50%, Fe: Balance |

| CTE (20–300°C) | ~6.0 × 10⁻⁶ /°C |

| Density | ~8.2 g/cm³ |

| Tensile Strength | 500–700 MPa (annealed) |

| Yield Strength | ≥ 300 MPa |

| Elongation | ≥ 25% |

| Electrical Resistivity | ~0.47 μΩ·m |

| Magnetic Permeability | Moderate |

| Melting Point | ~1450°C |

| Available Wire Diameters | 0.02 mm – 2.0 mm (customizable) |

| Surface Condition | Bright / Annealed / Oxidized |

| Packaging | Plastic spool, coil, or custom |

Precision alloys are metal materials with special physical properties (such as magnetic, electrical, thermal and other properties). The vast majority of precision alloys are based on ferrous metals, and only a few are based on non-ferrous metals. Usually include magnetic alloys (see magnetic materials), elastic alloys, expansion alloys, thermal bimetals, electrical alloys, hydrogen storage alloys (see hydrogen storage materials), shape memory alloys, magnetostrictive alloys (see magnetostrictive materials), etc.

Soft magnetic alloys are a class of alloys with high permeability and low coercivity in weak magnetic fields. According to the different elements that make up the alloy, it can be divided into electromagnetic pure iron (industrial pure iron), iron-silicon alloy, iron-nickel alloy, iron-aluminum alloy, iron-silicon-aluminum alloy and iron-cobalt alloy, etc.1J06,1J12,1J17,1J18,1J22,1J30,1J36,1J38,1J46,1J50,1J51,1J54,1J76,1J77,1J79,1J80,1J85,1J87

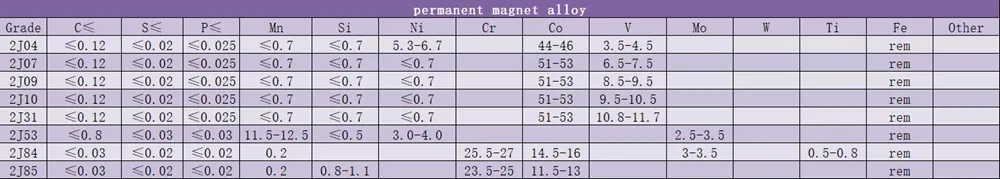

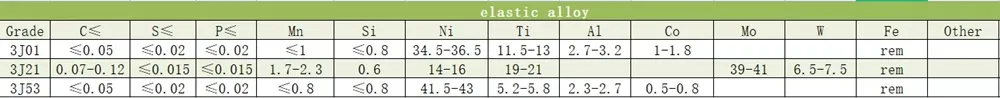

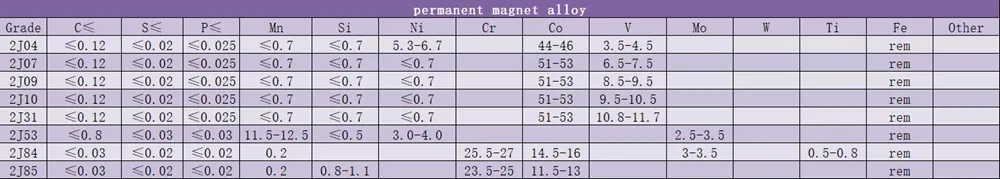

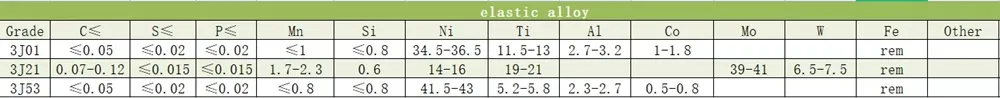

Permanent magnet alloy not only has high hardness and mechanical properties, but also has strong anti-demagnetization ability, high coercivity value (greater than 20kA/m), magnetic "hard" and other characteristics, so it is also called hard magnetic alloy.2J04,2J07,2J09,2J10,2J31,2J53,2J84,2J85 Elastic alloys include high elastic alloys and constant elastic alloys. It is used to make elastic elements such as elastic sensitive elements, energy storage elements and frequency elements in precision instruments.3J01,3J21,3J53

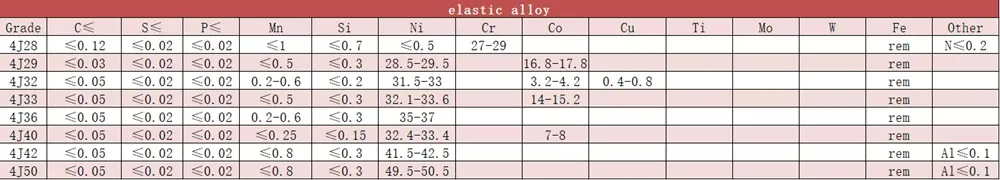

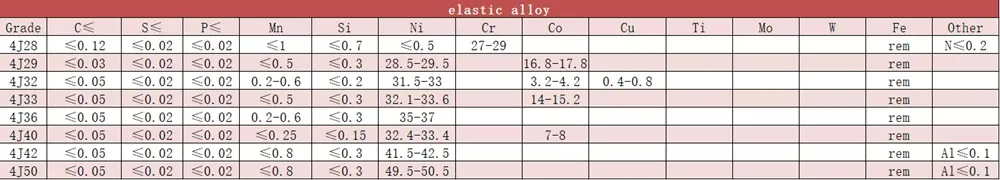

Elastic alloys include high elastic alloys and constant elastic alloys. It is used to make elastic elements such as elastic sensitive elements, energy storage elements and frequency elements in precision instruments.3J01,3J21,3J53 Expansion alloys(Invar Alloy) are divided into Kovar alloys, ceramic sealing alloys, low expansion alloys, and constant expansion alloys. Widely used in electronic industry, precision measuring tools, precision instruments and low temperature engineering and other fields.4J28,4J29,4J32,4J33,4J36,4J40,4J42,4J50

Expansion alloys(Invar Alloy) are divided into Kovar alloys, ceramic sealing alloys, low expansion alloys, and constant expansion alloys. Widely used in electronic industry, precision measuring tools, precision instruments and low temperature engineering and other fields.4J28,4J29,4J32,4J33,4J36,4J40,4J42,4J50

Precision alloys with nickel, chromium, aluminum and iron as the main components, the resistivity is about three times higher than that of manganese copper, and has a lower temperature coefficient of resistance and low thermal potential to copper, with good long-term resistance stability and resistance. Oxidation properties.

Precision alloys with nickel, chromium, aluminum and iron as the main components, the resistivity is about three times higher than that of manganese copper, and has a lower temperature coefficient of resistance and low thermal potential to copper, with good long-term resistance stability and resistance. Oxidation properties.

It is suitable for making precision resistance elements in various measuring instruments and meters, making precision micro-resistance elements and strain gauges.6J10,6J15,6J20,6J22,6J23,6J24

| expansion alloy | ||||||||||

| Grade | C≤ | S≤ | P≤ | Mn | Si | Ni | Cr | Cu | Al | Fe |

| 6J10 | ≤0.05 | ≤0.01 | ≤0.01 | ≤0.3 | ≤0.2 | nI+cO rem | 9-10 | ≤0.2 | ≤0.4 | |

| 6J15 | ≤0.05 | ≤0.02 | ≤0.03 | ≤1.5 | 0.4-1.3 | 55-61 | 15-18 | ≤0.3 | rem | |

| 6J20 | ≤0.05 | ≤0.01 | ≤0.01 | ≤0.7 | 0.4-1.3 | rem | 20-23 | ≤0.3 | ≥1.5 | |

| 6J22 | ≤0.04 | ≤0.01 | ≤0.01 | 0.5-1.5 | ≤0.2 | rem | 19-21.5 | 2.7-3.2 | 2-3 | |

| 6J23 | ≤0.04 | ≤0.01 | ≤0.01 | 0.5-1.5 | ≤0.2 | rem | 19-21.5 | 2-3 | 2.7-3.2 | |

| 6J24 | ≤0.04 | ≤0.01 | ≤0.01 | 1.0-3.0 | 0.9-1.5 | rem | 19-21.5 | 2.7-3.2 | ≤0.5 | |

Constantan alloy

Manganese Copper Alloy

| Brand | Ni | Mn | Cu | |

| Constantan alloy | 6J40 | 39-41 | 1-2 | Rest |

| Manganese Copper Alloy | 6J12 | 2-3 | 11-13 | Rest |

Recommended Products

Elastic alloys include high elastic alloys and constant elastic alloys. It is used to make elastic elements such as elastic sensitive elements, energy storage elements and frequency elements in precision instruments.

Elastic alloys include high elastic alloys and constant elastic alloys. It is used to make elastic elements such as elastic sensitive elements, energy storage elements and frequency elements in precision instruments. Expansion alloys(Invar Alloy) are divided into Kovar alloys, ceramic sealing alloys, low expansion alloys, and constant expansion alloys. Widely used in electronic industry, precision measuring tools, precision instruments and low temperature engineering and other fields

Expansion alloys(Invar Alloy) are divided into Kovar alloys, ceramic sealing alloys, low expansion alloys, and constant expansion alloys. Widely used in electronic industry, precision measuring tools, precision instruments and low temperature engineering and other fields